Micro welding can be executed using different welding process. Some of the actual industrial solutions are as follows:

The laser is in the solid-state. Automated programmable or manual machines are used in this accurate welding process. Micro laser welding provides the best welding quality thanks to its penetration power.

This technique does not apply pressure on the surfaces that are welded. Also there is no need for a vacuum chamber since the laser beam can travel through the air easily. There is no need to use shielding gas, but can be used for some applications. This method can be used for welding the highly reactive metals.

This technique is very useful as it does not produce any environment contaminating gas.

TIG micro welding

This uses equipment capable of very accurate control of just a few amps output power. The welding torche used for this type of micro welding is the size of a pen.

This technique is useful in welding very small components of high alloy density.

Flash micro welding

Flash micro welding uses high pressure to produce cost-effective and high-quality joints. This welding process is used to weld components as thermocouple wires.

The welds obtained with flash micro welding are good looking joints. Many beautiful chains of precious metals are built using this welding technique.

Another typical application is the joining of band saw or cable ends with great precision and quality.

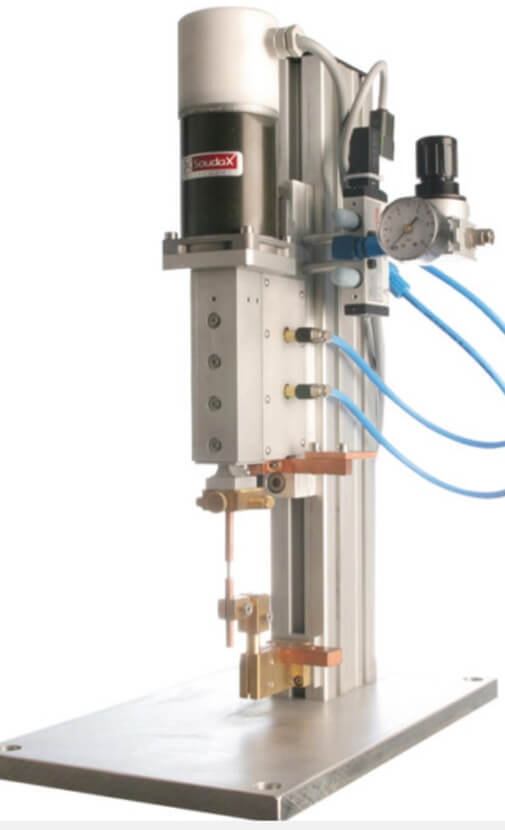

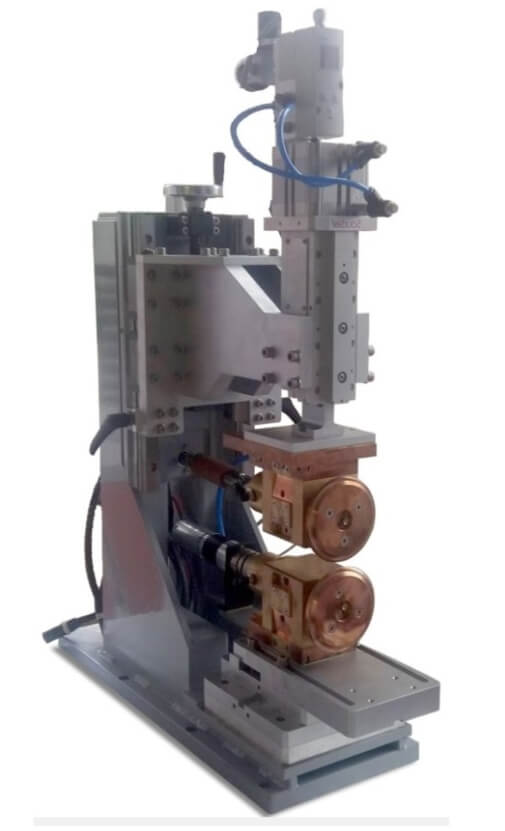

Resistance micro welding

This technique is derived from large scale resistance welding.

In micro resistance welding, the spot welds are performed with high precision and quality. This process needs very tiny electrodes for operation. The electrodes supply proper current for welding while pressure is applied by the welder.

This technique is suitable for the proper alignment of micro-elements. The high-quality projection welding can be performed using this resistance micro welding.

Another interesting variation of this process is the welding of micro-balls that are used as “tack-welds” to hold together components that will be welded later on using brazing or a different welding technique.

Recomendations for Micro-Welding

The micro welding technique requires an expert welder. The welder must have all suitable equipment for the process.

Each application require an expert aproach in order to find the technique that best fits the needs and requirements.

Let our experts guide you in the most adequate technique for your particular application.