For the Qualification of Welding Procedures, tube of the same material was cut and curved as the jacketing semi-cylinders. This ensured that the mechanical properties obtained in the tests would indicate the exact behavior of the welded cylinders in service.

The essential variables of qualifications were defined on the basis of the ASME, Sections VIII and IX Code,because it is a very high pressure gas conduction and because it is this code that brings the most experience in the behavior of these types of components: The choice of code and project requirements are essential. In the absence of requirements on the part of the customer, except for the integrity of the pipe and the realization of the repairs keeping the tube in full load, the SCWI defined this code as the safest for elaboration of the WPSs of the project.

Welders were also approved during the execution of the PQRs. All Solysol welders who participated in the project are experts in carrying out high-responsibility work. Our welder instructor, Fernando Sánchez Deza, in addition to performing most of the repair, acted as a welding coordinator during the entire project. Welders José Pinto and Braulio Condori did an excellent job. No weld performed throughout the entire project required any repair. And, in particular, they worked aware of the responsibility and risk of welding on a high pressure and flow gas-fired tube, traversing the corrosion zone with the proper procedure to ensure the integrity of the tube and their own lives.

The customer’s trenching and handling staff in Morocco proved essential for the repair project as well.

Choosing an excellent electrode ensures the mechanical properties of welds and helps welders to make each bead flawless, with easy-to-clean surface slag that is not trapped at the edges of the beveled joints. ESAB FILARC 98S electrode, with the same mechanical properties as the base metal, provided excellent tensile yield & strength, and toughness at -20oC.

The necessary tests and control of the weld execution is performed by a CWI, Certified Welding Inspector by the American Welding Society (AWS). All work is scheduled, supervised and approved by a SCWI (Senior Certified Welding Inspector),Angela Lazaro.

The staff dedicated to repairs of great responsibility, as in this work, has a great experience, qualification and certification. In addition, their continuous training and study and their passion for the work they do are an excellent guarantee for customers who have this type of needs.

Linear pitting corrosion throughout the perimeter of the tube at an average distance of 200-300 mm from the original pipe welded joint.

Linear pitting corrosion throughout the perimeter of the tube at an average distance of 200-300 mm from the original pipe welded joint.

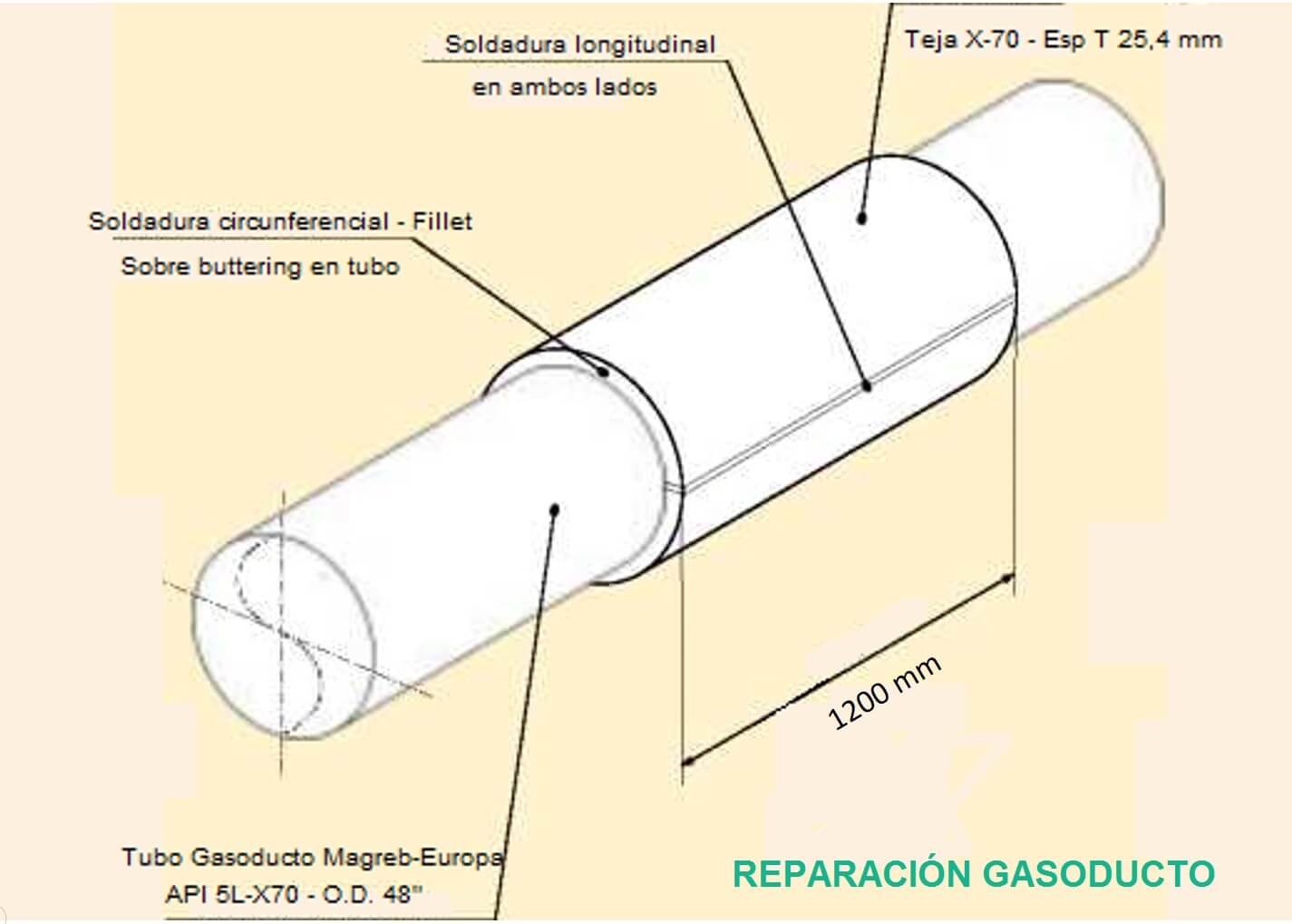

Procurement of material for making the half-cylinders that will form the jacketed to cover the damaged area, of the same characteristics of the steel of the original tube: API 5L-X70, thickness 25.4 mm (1″).

Procurement of material for making the half-cylinders that will form the jacketed to cover the damaged area, of the same characteristics of the steel of the original tube: API 5L-X70, thickness 25.4 mm (1″). Cutting and bending of semi-cylinders to wrap the damaged section of the original tube.

Cutting and bending of semi-cylinders to wrap the damaged section of the original tube.

Preparation of the edges of the semi-cylinders with S460 steel plate to insert a secure backing into both longitudinal joints to conform the tubular jacket.

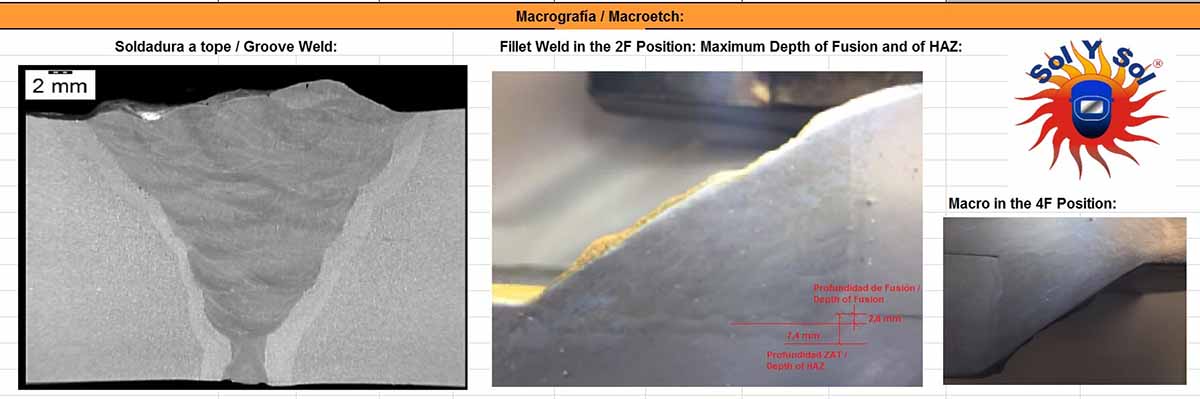

Preparation of the edges of the semi-cylinders with S460 steel plate to insert a secure backing into both longitudinal joints to conform the tubular jacket. Performing “buttering” or surfacing welding on both sides of the tubular jacket to provide the right support for the fillet welding around the full perimeter of the joint from the jacket to the original tube.

Performing “buttering” or surfacing welding on both sides of the tubular jacket to provide the right support for the fillet welding around the full perimeter of the joint from the jacket to the original tube.

Placing the semi-cylinders to form the jacketing in the area to be repaired of the tube in service.

Placing the semi-cylinders to form the jacketing in the area to be repaired of the tube in service.

Continuous control of the preheating temperature and maintenance in the entire perimeter and longitudinal areas of the areas adjacent to the weld.

Continuous control of the preheating temperature and maintenance in the entire perimeter and longitudinal areas of the areas adjacent to the weld.