Description of Necessary Equipment

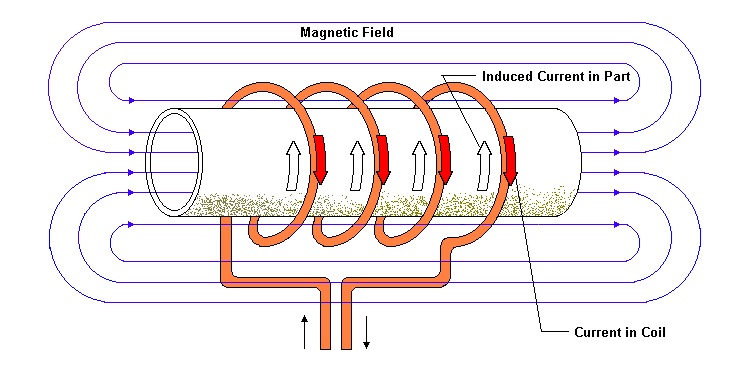

The basic equipment is, today, relatively simple. Basically, a source of high-frequency alternating current is required and elements for conducting said current that can be arranged on the component that needs to be heated or treated effectively.

It should be taken into account that a wrong configuration or an inappropriate choice of the elements that make up the necessary equipment, can result in an undesired temperature distribution and, therefore, a significant or even catastrophic detriment to mechanical or dimensional properties of the component in question.

For the application of the process, it is necessary to have the necessary knowledge of the effects of temperatures on the materials and experience on the most appropriate configuration for each application, or otherwise, it will result in a very risky practice.

In industrial applications, perhaps due to the means available at all times, users are not shocked by practices that would be unthinkable in domestic applications, although the effects are equally comparable. Nobody would think of roasting a food by putting it directly over a flame or over a red resistance: its surface would be completely scorched while the inside would be completely raw. If this is so obvious, how do we heat metallic materials, knowing the effects that temperatures and heat treatments cause on their metallographic structures and consequently on their properties, using techniques that we would never use with food?

A possible way of classifying induction heating equipment is according to the desired temperature of the components to be heated and, therefore, the type of heat treatment that is carried out. Thus, we can have:

Preheating Equipment:

- For temperatures in the components to be heated up to 204 ° C (400 ° F)

- Air cooled systems

Heat Treatment Equipment:

- For temperatures in the components to be heated up to 788 ° C (1450 ° F)

- Water-cooled systems, or also air-cooled, providing adequate insulation to the cables

- They can also be used for preheating at lower temperatures

- For dehydrogenation treatments

- For Stress Relieve and PWHT treatments

- For fitting / unlocking components in assembly by means of homogeneous expansion

- And many other applications